“They don’t make them like they used to” – it’s a phrase often said with nostalgia and a bit of disappointment. Yet, although today’s testing equipment may not share the tank-like construction of its predecessors, it more than makes up for them in capability. An electrician’s van used to almost groan under the weight of specialised testing equipment, each device dedicated to a single task – but nowadays, today’s lightweight digital tools pack the equivalent of an entire workshop into a single handheld device.

When Bruce and Marlene Henderson established BW Henderson Electrical in Papakura in 1952, their vision was straightforward: deliver exceptional electrical services with reliability and attention to detail. The tools they used then were robust but rudimentary – a far cry from today’s sophisticated equipment.

So, when Chris French acquired BW Henderson Electrical last year and unearthed a shelf-load of dusty vintage electrical equipment, it was a nostalgic return to his roots. In his early days, Chris grew up surrounded by this era of equipment at his father, Richard’s, French Electrical workshop. For Chris, it told stories of a time when durability wasn’t just a feature – it was a basic manufacturing principle.

“Holding the clamp meter from the 1970s, I couldn’t get over how well-made it is. It’s crazy to think about all the circuits these tools have tested and the problems they’ve helped solve over the decades. Some of these devices have probably outlasted the electrical systems they were first used to service,” says Chris.

The collection, some pieces dating back to the 1950s, represents more than just stored equipment – it’s a reminder of a time when tools were built to outlast their owners. Housed in robust metal casings and wrapped in hand-stitched leather cases, each piece shows the wear and tear of countless service calls and challenging repairs. But while these vintage tools command respect for their durability, they also highlight how far electrical testing technology has evolved.

The digital revolution in electrical testing has changed every aspect of the trade. Modern tools don’t just perform tests – they analyse, record, and share data in real-time. What once required physical effort and manual calculation has evolved into easier digitalised processes that enhance both efficiency and safety.

The clamp metre – now a diagnostic tool

Consider the clamp meter. This electrical testing device is designed to clamp around electrical cables to measure current flow without breaking the circuit. Old testers were big and heavy, but they could only measure simple things. Modern testers are small, light and clever – they can send results to your phone and computer, letting you share test readings right away with others. They can handle bigger power loads and save all the information, which is perfect for modern electrical systems.

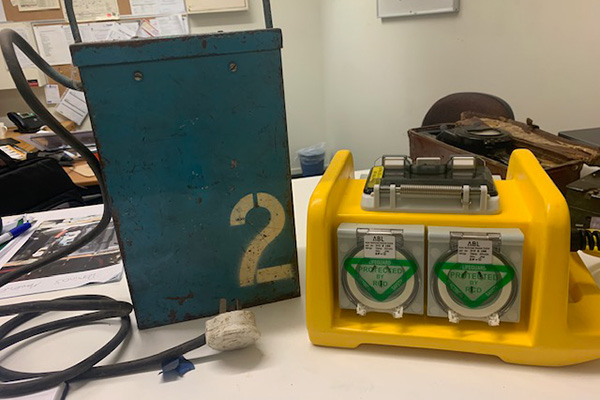

The isolation transformer – built like a tank

The transformation of safety equipment is just as dramatic. Traditional isolation transformers, weighing a substantial 10 kilograms, used to be built like tanks and were equally as heavy.

Old power boxes were essential on building sites and events – they connected to the mains power and passed it safely to different tools and equipment.

While heavy to carry around, they were tough and reliable. Today’s power boxes do the same job but are much lighter and smarter – they have built-in safety switches that cut power instantly if something goes wrong, plus digital screens that show you exactly how much power is being used. This makes them much safer and helps prevent overloading.

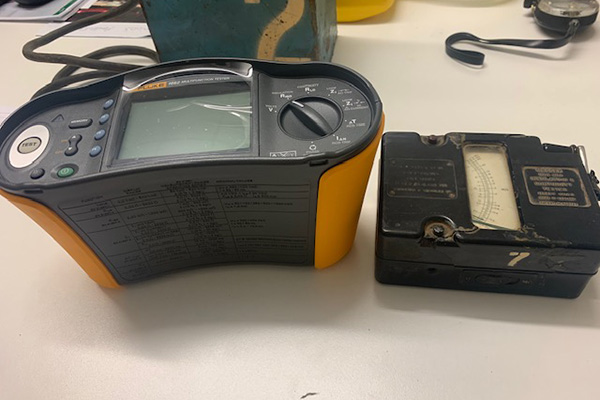

Multi-function testers now log and analyse data

The journey from vintage Megger testers to modern Fluke multi-function testers is a real leap in electrical testing technology. A Megger is an old-style tester that only checks for safely insulated wires.

Modern testers are much better, because they do many safety checks all at once – they test the insulation, check if safety switches work, and measure electrical flow, all using one simple digital device instead of needing lots of separate tools. The ability to log and analyse data has really changed how electricians document and track electrical system performance over time.

When electricians choose electrical equipment today, they need to consider more than just the basics. The best tools offer a combination of reliability and advanced features that improve workplace efficiency. Modern equipment has diagnostic software while still maintaining the robust dependability that has always been a hallmark of quality electrical tools.

The evolution from Bruce Henderson’s original toolkit to the advanced equipment used today illustrates not only technological progress but also the industry’s dedication to ongoing improvements in service, safety, and reliability. Although the tools have changed, the fundamental commitment to delivering high-quality electrical work remains as strong as ever.

As BW Henderson continues to serve the South Auckland community, it does so with a deep appreciation for its heritage and an eye toward future innovations shaping the next chapter in electrical services.

Contact us today to learn more about our services for your home or business project.